INFORMATION

High-Speed System

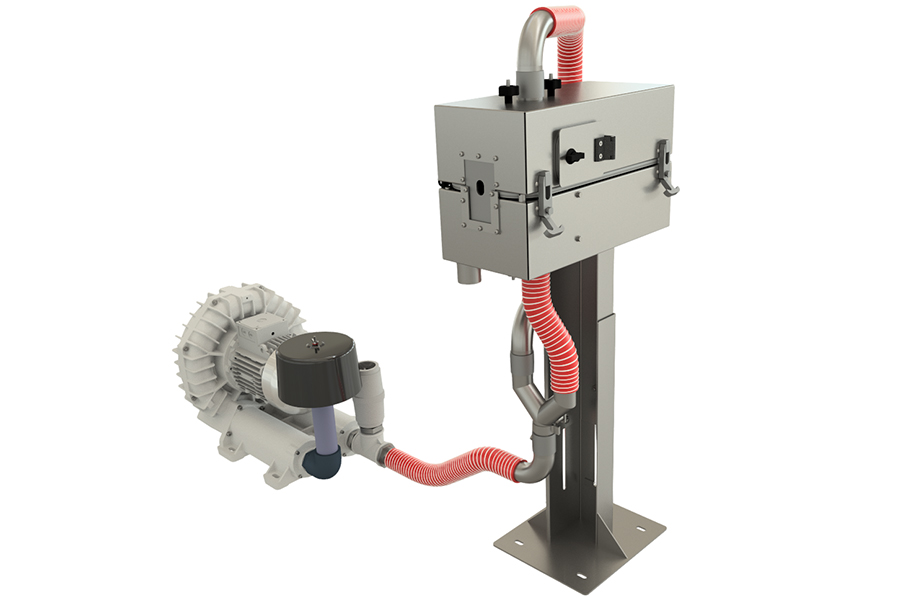

ACI’s high speed drying system is fully enclosed and has a height adjustable stand which allows it to be easily positioned into most lines without any issues. Round product profiles, with diameters between 0 and 4mm can be successfully dried at maximum line speeds of up to 1,000m/min.

. Overview – Cable & Wire Systems

Overview – Cable & Wire Systems

If you would like to discuss the suitability of this system for your application, please contact us.

General Characteristics:

Discharge Figures

Pressures >500mbar

Air Temperature: 80 Deg.C (176 Deg.F.)

Air Speed: 12,900m/min (42,300ft/min)

Product Capabilities

Up to 4mm diameter

Running speeds of 1,000m/min

Noise Levels

Below 74dB(A) for blower

Motor Details

Motor power 5.5/6.3kW

400VY/690VD, 50Hz

460VY/795VD,60Hz

3Ph, 400/480V, 50/60Hz

Materials

Face plates and drying head end-caps:

Polyethylene PE1000; Connecting hose:

thermoplastic rubber

What’s inside?

ACI’s High-Speed Cable Drying System is a self-contained, blower-driven unit that uses precisely controlled air flow that reduces noise and dramatically cuts energy consumption.

It works by closely focusing powerful angled air jets against the flow of the product. These air jets are opposing, and aim at the top and bottom of the product to hold back the advancing residual moisture. This is achieved by breaking the surface tension of the water, allowing it to gather and be stripped from the product.

Soft edged flexible rubber baffles then form a torturous path to help catch and contain the resultant spray preventing it exiting the enclosure to avoid causing potential water related H&S issues.

The removed water drains from the enclosure which could be piped back into the system to save costs and improve processes. The baffles are able to flex enough to allow knots and other line impurities to pass without consequence, along with the sprung loaded plenums which house the air jets.

The Power Pack

The high-velocity air is supplied to the system by a 5.5kW Side Channel Blower through high temperature flexible ducting. The unit includes a safety pressure relief valve and inlet filter.